Organic Fumigation Using Either CO2 or Nitrogen

This article is one in a series that are based on presentations given at the 14th Stored Product Protection Conference hosted by Insects Limited and held at Purdue University on June 14 & 15, 2023. The 2-Day conference that focused on protecting our food and cherished belongings from pests had 140 people attend from 6 continents and 24 different countries. This presentation given by Insects Limited president Patrick Kelley covered the pros, cons and stumbling blocks of using carbon dioxide (CO2 ) or nitrogen as organic fumigants on organic food products.

by Patrick Kelley, BCE

Organic Fumigation Using Either CO2 or Nitrogen

One of the many data points that has drastically changed over the past 20 years is the sheer amount of organic food that is consumed in the world today.

In the United States, the retail sales of organic food rose from 10 billion in 2001 to 55 billion in 2020. On a global scale, organic food sales rose from 15 billion in 1999 up to 132 billion in 2021.

There is no argument that more and more consumers are demanding organic foods and that the market must react to fulfill this demand.

From a pest standpoint, the nature of organic foods is adherently more at risk to pest attack than a non-organic equivalent. Organic foods are checked by governments and by certifying organizations to verify that no prohibited substances (E.g., common pesticides) encounter the soil, the crop, or the finished food product.

An important aspect of whether we can use carbon dioxide or nitrogen as a treatment is whether the organic certifying organizations allow their use. The National List of Allowed and Prohibited Substances identifies substances that may and may not be used in organic crop and livestock production. It also lists the substances that may be used in or on processed organic products.

The retail sales of organic food has risen dramatically over the past two decades. Image from https://www.statista.com/statistics/273090/worldwidesales-of-organic-foods-since-1999/

In general, synthetic substances are prohibited unless specifically allowed and non-synthetic substances are allowed unless specifically prohibited: https://www.ams.usda.gov/rules-regulations/ national-list-allowed-and-prohibited-substances.

Currently, non-synthetic, oil-free grades of nitrogen are allowed as organic treatments as well as synthetic, man-made (anthropogenic) carbon dioxide.

Organic operations are certified by private, foreign, or state entities that have been accredited by USDA.

Carbon Dioxide

Carbon dioxide (CO2 ) is one of the more commonly found gases on earth, but it has also been identified as a gas that has an indirect effect on the ozone layer in the stratosphere when excessive levels are emitted on earth. The amount of carbon dioxide used to treat pest infestations, though, is minuscule compared to the quantities produced in the air-sea gas exchange or through other industrial uses such as the generation of electric power.

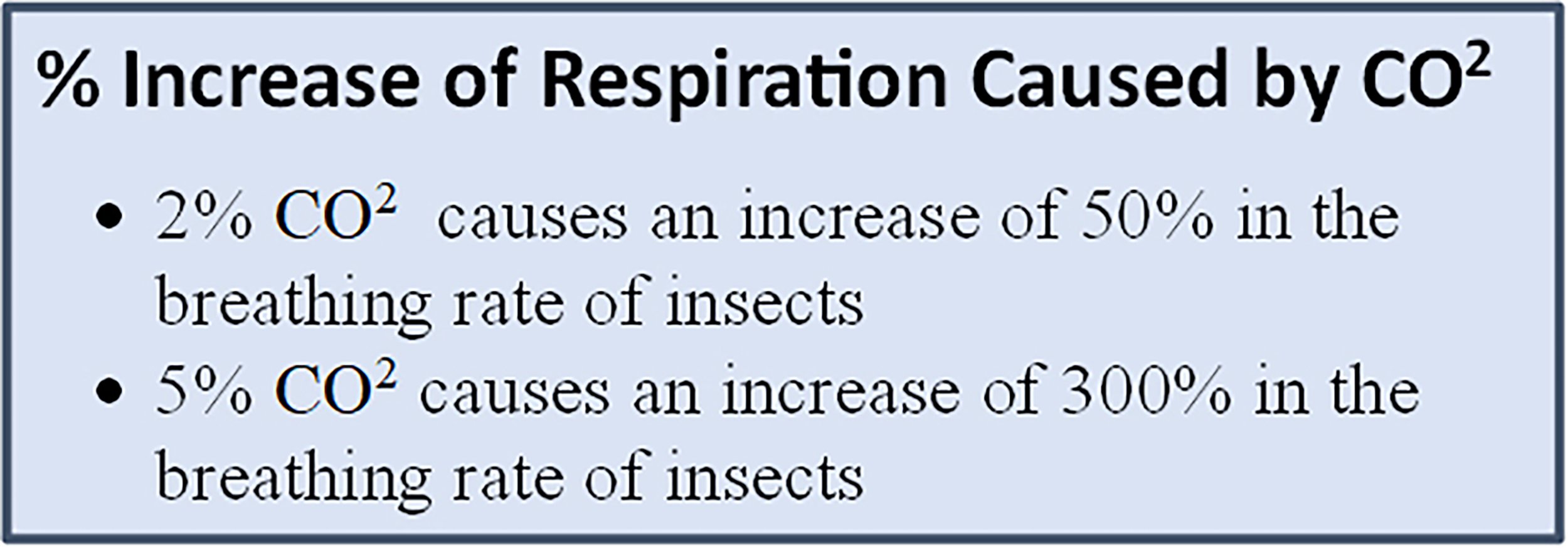

Hypercarbia, a word meaning elevated levels of carbon dioxide, is what kills insects and rodents when fumigating with CO2 . Oxygen deprivation (anoxia) in CO2 treatments leads to an increase in mortality rates, but it is desiccation, or dehydration due to increased respiration which specifically accounts for physiological death of pests.

Increased levels of carbon dioxide cause insect spiracles to remain open as the insect’s body tells it to get rid of excess CO2 . The open spiracles cause the insect to lose valuable water molecules and eventually leads to the insect dying from dehydration and desiccation. Image copyright: Insects Limited, Inc.

The effects of CO2 on the respiration of insects are significant. A 2% increase of carbon dioxide causes an increase of 50% in the breathing rate of insects. A 5% increase of CO2 causes an increase of 300% in the breathing rate of insects.

The means that increased respiration leads to the death of the insects can be explained by examining the way that insects breathe. Unlike mammals, insects do not breathe through their mouths, but instead through tiny holes in their exoskeletons. These tiny holes, called spiracles, open when the insect wants to take in oxygen but also open when the insect wants to get rid of waste carbon dioxide. The spiracles remain shut at all other times to retain water molecules in the insect’s body.

Spiracles of wood-boring beetles observed under SEM. Lyctus linearis (Goeze): A. Abdomen extremity of the larva with the last two spiracles; B. Penultimate abdominal spiracle; C. adult abdominal spiracle; D. Trichoferus holosericeus (Rossi), larval thoracic spiracle. From Chiappini, Elisabetta & Aldini, Rinaldo. (2011). Morphological and physiological adaptations of wood-boring beetle larvae in timber. The means that increased respiration leads to the death of the insects can be explained by examining the way that insects breathe. Unlike mammals, insects do not breathe through their mouths, but instead through tiny holes in their exoskeletons. These tiny holes, called spiracles, open when the insect wants to take in oxygen but also open when the insect wants to get rid of waste carbon dioxide. The spiracles remain shut at all other times to retain water molecules in the insect’s body. Journal of Entomological and Acarological Research, Ser. II. 43. 47-59. 10.4081/jear.2011.47. and The respiratory system of an insect, including spiracles. Encyclopedia Britannica (2012)

Increases in CO2 cause the spiracles to remain open as the insect’s body tells it to get rid of excess CO2 . Unfortunately for the insect and fortunate for those of us trying to eliminate a pest insect problem, the wide-open spiracles allow the valuable water molecules to escape from the insect’s body and the insect eventually dies of desiccation and dehydration. At this same time, high CO2 levels and lower oxygen levels prevent the insect from any energy gain. CO2 poisoning and suffocation can also be playing a role in speeding up the insect’s death.

The recommended times that a CO2 treatment takes varies greatly depending on where you are getting your information. The cylinderized CO2 product "IGI Carbon Dioxide Powered by Liphatech" lists the following on their pesticide label, “For storage and structural fumigation, dosage rates vary from 60% atmosphere to 88% atmosphere. Treatment times vary from 24 hours to 4 days. Do not fumigate if temperature is less than 40ºF. Structure should be as gas tight as possible before treatment. Maintain as near as 60% ±10% CO2 as possible.”

The time frame on the pesticide label for IGI Carbon Dioxide Powered by Liphatech above is much shorter than what is recommended on some well-respected museum websites or in several museum-based scientific papers on CO2 treatment.

MuseumPests.net, a great resource for all pest issues found in museums says this about treatment time:

“Treatment time is typically four weeks in the ‘kill zone’ range: 4.8% - 8.2% oxygen, 60% CO2 at 20-29ºC (68-84ºF). Updated methods show that treatment times can be reduced by increasing the initial CO2 to 80% within the first five days. From this point on, 14 days are necessary to kill all species. During this period it is imperative that the CO2 does not fall below 60% and temperatures do not fall below 80º F.”

The reason for the differences in exposure time might have to do with relative humidity (RH). When cylinder-based carbon dioxide is used in a treatment, it is a dry gas with no water molecules. Pumping large amounts of carbon dioxide into an enclosure can quickly drop the RH % to levels of 10% or even lower. When treating dried food goods or grains, lower RH levels do not have negative consequences on the food products.

The dried foods and grains often have initial internal RH percentages in the teens and the food has a chance to rebound to a normal level after the treatment. The same is not true when treating museum objects. A drastic drop in RH can negatively and permanently affect a museum object.

Museum conservators and curators generally try to keep valued collections as environmentally stable as possible and as close to an RH of 50% as possible. Considering the difficult task that museum professionals have of attempting to keep objects in the same condition 500+ years from now as they are today, makes this standard a bit easier to understand.

The 50% RH during a museum fumigation that uses CO2 is often achieved with humidifiers pumping moisture into the enclosure throughout the duration of the treatment. Since desiccation and dehydration are the factors killing the insects, the higher RH for museum objects during treatment is likely keeping the insects alive longer.

This may explain why longer times (3 - 4 weeks) are recommended and needed for museum treatments with CO2 while only 1 - 4 days are specified on the IGI Carbon Dioxide Powered by Liphatech label for food and grains.

One of the drawbacks of a carbon dioxide treatment is that it is difficult to contain this active gas molecule and retain the levels needed to kill insects. The oxygen in ambient air on the outside of the treatment enclosure is actively trying to get inside.

For these reasons, entire-structure carbon dioxide fumigation is not cost effective and not recommended unless significant investment is made into specifically modifying the structure to make it gas impermeable. Standard polyethylene sheeting (<6mm thick) will not suffice as a barrier as it only slows the egression of CO2 and the ingress of oxygen.

Eventually CO2 levels drop below what is needed to kill insects using standard polyethylene. HDPE, Nylon, EVOH or multi-layered plastic and foil barrier films are a better option to contain CO2 and keep oxygen from entering the treatment area.

Nitrogen

When nitrogen is being used as the treatment gas, it works much differently on the insect than carbon dioxide does. Where carbon dioxide is killing insects through desiccation, dehydration and carbon dioxide poisoning (hypercarbia), nitrogen is killing insects through suffocation alone by creating an anoxic environment. While carbon dioxide levels only need to be at 60% - 80% to be effective, the level of nitrogen needs to be near a level of >99.7% which translates to <0.3% oxygen. Some recent research suggests that levels of 1% oxygen are satisfactory to kill insects in certain situations. The nitrogen being introduced forces the oxygen out of the fumigation enclosure. Standard breathing air is made up of 78% nitrogen, 21% oxygen, 0.04% CO2 and 0.96% other gases (mostly argon). The job of the fumigator is to force the 21% oxygen in the breathing air out of that enclosure to an acceptably low level and keep it out for at least a 3-week period.

The reason it takes so long to suffocate an insect (Humans would suffocate within minutes at oxygen levels of 5%) is that as soon as oxygen levels begin to dip, insects stop moving, they close their breathing spiracles, and they retain any oxygen that they previously had in their system. Since they are not moving, they are not using energy and thus only use incrementally small amounts of oxygen.It can take up to a full 3 weeks before insects use up the oxygen supplies that they hold within their bodies prior to suffocation. The most inactive stages of insect, the pupal and egg stage, tend to live the longest under low levels of oxygen.

After using nitrogen to flush out the oxygen in breathing air, and holding those low levels (<0.3%), insects will finally suffocate after 3 weeks. Image copyright: Insects Limited, Inc.

When performing Anoxic treatments, different styles of enclosures can be used. The company Hanwell makes prefabricated Anoxic Storage Solutions for use with oxygen scavengers. Iron shavings that make up the scavengers chemically react with oxygen molecules, consuming the oxygen. The end-product after the reaction is iron oxide (rust).

As stated above, whenever considering a carbon dioxide or anoxic treatment, the type of barrier material used in the enclosure is of the utmost importance. CO2 and oxygen have extremely small, active gas molecules that are not easily contained.

Hanwell’s enclosures use a multi-layered foil barrier that can be heat-sealed to keep oxygen out after the existing oxygen has been consumed. Soft-sided enclosures (GrainPro, Maheu Fumigation Bubble, Heritage Packaging, etc.) use PVC plastics to contain the gas molecules, while hard-sided permanent chambers (Vacudyne Inc., etc.) use metal walls with sealable doors to contain the gas. If using standard polyethylene, a thickness of >6 mils is necessary.

Costs for the different enclosures can vary greatly. Smaller Hanwell enclosures can be purchased for slightly over $100 USD, larger, custom soft-sided enclosures can be made for ~$20,000 USD while a permanent, metal, hard-sided chamber may run ~$200,000. USD.

It is important to evaluate what you will be creating a modified atmosphere for, when planning your organic fumigation. You will need to ask yourself what space you will be using, what resources (electricity, temperature controls, etc.) are available in that space and what budget that you have prior to deciding.

The need for organic fumigations has risen dramatically over the past decade. Effective solutions are out there if you consider all these parameters.

Both soft-sided mobile and hard-sided permanent fumigation chambers can be used when performing organic fumigations with carbon dioxide or nitrogen. Shown here are GrainPro’s cocoon on the left and QVS Vacuum Fumigation Chamber on the right.

Related Insect and Pheromone Posts

Read more about insects and pheromones in these related posts:

Product of the Month - PTL Multi-Species Kit (IL-408-10)

Insects Limited, an Insect Pheromone Company

Insects Limited, Inc. researches, tests, develops, manufactures and distributes pheromones and trapping systems for insects in a global marketplace. The highly qualified staff also can assist with consultation, areas of expert witness, training presentations and grant writing.

Insects Limited, Inc. specializes in a unique niche of pest control that provides mainstream products and services to protect stored food, grain, museum collections, tobacco, timber and fiber worldwide. Please take some time to view these products and services in our web store.